Garage Door Bearing Plate: Repair, Replacement, and Maintenance

If your garage door has started making grinding noises, jerking as it opens, or feeling unusually heavy and uneven, it’s easy to assume the problem lies with the opener. While a failing opener can cause these symptoms, there’s another culprit that homeowners often overlook: the garage door bearing plate—specifically the end bearing plates or center bearing plate that support the torsion shaft above the door.

Although bearing plates are relatively small components, they play a vital role in keeping your garage door balanced, safe, and running smoothly. When bearing plates wear out, they can cause rough door operation, strain torsion springs, damage drums and cables, and even shorten the lifespan of your garage door opener.

This guide follows a simple, practical framework for understanding bearing plate issues:

Assess → Repair → Replace → Maintain

We’ll walk you through how to identify problems, repair minor issues, and know when it’s safer to call a professional like A1 Garage Doors Gold Coast, serving the Gold Coast and parts of Brisbane.

What Is a Garage Door Bearing Plate?

A garage door bearing plate is a steel bracket mounted to the wall or header above your garage door. Its main function is to hold a bearing that supports the torsion shaft (torsion tube)—the metal bar around which torsion springs wind to lift the garage door.

Types of Bearing Plates

1. End Bearing Plates: Mounted at the left and right ends of the torsion shaft. These support the shaft ends near the cable drums.

2. Center Bearing Plate: Mounted near the middle of the shaft, usually between torsion springs, to prevent the shaft from sagging.

These bearings reduce friction and allow the torsion shaft to rotate smoothly as the door opens and closes. A malfunctioning bearing plate can lead to uneven operation, increased wear, and even serious safety hazards.

Functions of Bearing Plates

When your bearing plates are in good condition, they:

* Keep the torsion shaft properly aligned and supported

* Reduce stress and binding on torsion springs

* Prevent cable drift and uneven drum rotation

* Extend the life of related components such as drums, cables, rollers, and the garage door opener

If your garage door is making unusual noises, it’s wise to consult a broader diagnostic checklist first: Garage Door Troubleshooting Guide

Signs Your Bearing Plate Needs Repair or Replacement

Bearing plate problems often give early warning signs. Watch for:

* Grinding, squeaking, or popping noises near the torsion shaft

* Jerky or uneven movement (door “catches,” shudders, or sticks)

* Door feels heavy or struggles to lift

* Visible rust or corrosion on the plate or bearing

* Wobbling shaft or misaligned drums/cables

* Excessive vibration transmitted through the door

Catching issues early can prevent costly repairs and improve garage door safety.

Common Causes of Bearing Plate Failure

Several factors can contribute to bearing plate wear and failure:

* Lack of lubrication: Dry bearings increase friction, noise, and wear

* Rust and corrosion: Especially common in coastal areas

* Heavy doors: Extra weight puts stress on bearings and plates

* Age and normal wear: Bearings often last 10–15 years under typical usage

* Improper installation: Plates installed out of plumb or shafts misaligned can fail prematurely

End vs Center Bearing Plates: What’s the Difference?

Understanding the differences helps you determine whether a DIY repair is feasible or if professional intervention is required.

| Component | Location | Purpose | DIY Difficulty | Risk Level |

|---|---|---|---|---|

| End Bearing Plate | Left/right ends of torsion shaft | Supports shaft ends near cable drums | Moderate | High (torsion) |

| Center Bearing Plate | Middle of shaft (between springs) | Supports shaft center, prevents sag | High | Very High |

Key takeaway:

* End bearing plate work may be manageable for skilled DIYers with mechanical experience.

* Center bearing plate replacement usually involves handling torsion springs and should be left to trained professionals.

If spring or cable issues are suspected, professional intervention is the safest path: Emergency Garage Door Repair

Assess → Repair → Replace → Maintain

Step 1: Assess the Problem

Before buying parts or attempting a repair, perform a quick assessment:

* Is the noise coming from above the door, near the torsion shaft?

* Does the noise reduce temporarily after lubrication?

* Is the torsion shaft wobbling at either end?

* Are the cables evenly seated on the drums?

* Does the door move unevenly or shake?

If your door struggles to open or the opener sounds strained, review additional guidance: Garage Door Opener Comparison

Step 2: Repair Option (Lubrication)

If the bearing plate is not cracked, bent, or heavily rusted, and the bearing still spins freely, a service and lubrication may resolve minor issues.

How to Lubricate Bearing Plates Safely:

1. Close the door fully.

2. Disconnect power to the opener for safety.

3. Apply a garage-door-safe grease or lubricant to the bearing (avoid spraying directly on the spring coils).

4. Wipe off any excess grease.

5. Run a manual test cycle.

If the noise returns quickly, the bearing is likely worn and requires replacement.

Step 3: End Bearing Plate Replacement

Safety First:

Torsion systems are under extreme tension. Even replacing an end bearing plate involves proximity to high-risk components. DIY replacement is only recommended if you:

* Are mechanically confident

* Understand torsion shaft alignment

* Have proper tools and personal protective equipment (PPE)

Otherwise, hire a professional like A1 Garage Doors Gold Coast.

Tools and Materials Needed:

* Socket wrench and pliers

* Garage door lubricant/grease

* Replacement end bearing plate

* Ladder

* Safety gloves and glasses

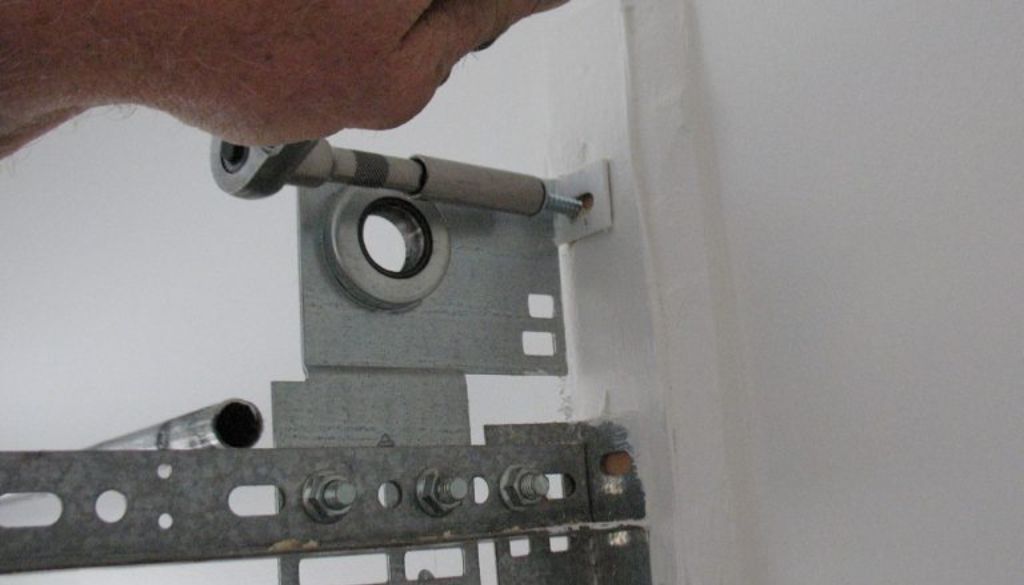

Step-by-Step Replacement:

1. Open the garage door fully. Use the opener carefully or manual supports.

2. Unplug and disengage the opener.

3. Confirm the torsion shaft is stable and drums/cables are seated.

4. Support the torsion shaft if needed.

5. Loosen and remove the bolts securing the old end bearing plate.

6. Slide the old plate off the shaft.

7. Position the new plate and ensure it is plumb.

8. Reinstall bolts securely.

9. Lubricate the bearing lightly.

10. Check that cables are still seated properly on the drums.

11. Test door manually before re-engaging the opener.

Warning: If you notice cable or spring issues during replacement, stop and call a professional. Improper handling can be dangerous.

Step 4: Center Bearing Plate Replacement

The center bearing plate sits near the torsion springs and often requires:

* Unwinding torsion spring tension (specialized tools needed)

* Removing or shifting torsion tube sections

* Resetting and balancing the system

Due to high risk, this replacement should always be performed by trained technicians. Signs that the center bearing may need replacement include noise at the center, shaft sagging, or uneven cable wrap.

DIY vs Professional Replacement

| Factor | DIY | Professional |

|---|---|---|

| Safety | High risk (torsion system) | Safe, trained handling |

| Tools | Basic + mechanical experience | Specialized torsion tools |

| Cost | Lower if skilled | Higher upfront, avoids damage |

| Time | 1–3 hours | 1–2 hours |

| Warranty | None | Often includes coverage |

Recommendation: If you’re dealing with a center bearing or unsure about torsion tension, hire a professional.

A1 Garage Doors Gold Coast specializes in torsion system repairs, openers, and installations throughout the Gold Coast and parts of Brisbane.

Preventative Maintenance for Bearing Plates

Regular maintenance extends the life of bearing plates and prevents expensive repairs.

Maintenance Checklist (Twice Per Year):

* Lubricate all bearings (end and center)

* Inspect plates for rust or corrosion

* Ensure bolts are tight and plates are plumb

* Observe cable wrap on drums for even placement

* Test door balance (door should hold midway without drifting)

Annual Recommendation: Book a professional inspection, particularly for coastal properties where corrosion accelerates wear.

Signs You Should Inspect Other Components

Bearing plate wear often coincides with other worn parts:

* Torsion springs (door feels heavy or unbalanced)

* Damaged drums (cables tracking incorrectly)

* Off-track door movement

* Noisy or stiff rollers

* Worn hinges causing vibration

Additional guidance: Garage Door Rollers & Hinges

Costs: What to Expect

Costs vary depending on the door type and number of bearings replaced:

* Parts: Bearing plates and bearings are relatively affordable.

* Labour: Depends on torsion configuration and whether springs must be unwound.

The value of professional service includes avoiding:

* Spring-related injury risks

* Misalignment causing premature wear

* Cable or drum issues leading to bigger failures

Frequently Asked Questions

How long do bearing plates last?

Typically 10–15 years, depending on door usage, environment, and maintenance.

Can I replace bearing plates without affecting the springs?

End bearing plates may be replaced with caution, but alignment is crucial. Center bearing plates usually require spring handling.

Do bearing plate failures damage other components?

Yes. Worn bearings can strain torsion shafts, springs, drums, cables, and openers.

Is it safe to lubricate a worn bearing plate?

Lubrication is safe for minor noise. For grinding, wobbling, or visible damage, replacement is the safer option.

Book a Bearing Plate Inspection (Gold Coast)

If your garage door is noisy, jerky, or unbalanced, it’s important to inspect bearing plates before the issue escalates.

A1 Garage Doors Gold Coast

(07) 5515 0277

1 Waterford Ct, Bundall QLD 4217

Operating since 2020, A1 Garage Doors has a strong local reputation for repairs, servicing, and maintenance across the Gold Coast and parts of Brisbane.

Proper assessment, timely repairs, and routine maintenance of your bearing plates can save you from costly repairs, prolong the life of your garage door system, and ensure smooth, safe operation for years to come.