Garage Door Torsion Bar Installation: What You Need to Know

Your garage door’s torsion bar and spring system is the powerhouse behind smooth, balanced operation. Whether you’re replacing worn springs or installing a complete new system, understanding how torsion bar installation works helps you make informed decisions about your garage door. This guide explains what torsion systems do, what professional installation involves, and why this is one job that absolutely requires expert handling.

Before attempting any work on your torsion bar system, it’s essential to understand why garage door spring replacement is dangerous—torsion bars store tremendous energy under tension and can cause severe injuries or fatalities if improperly handled without the correct tools and training.

What Is a Garage Door Torsion Bar?

A garage door torsion bar is the steel shaft that runs horizontally above your garage door opening. This bar holds the torsion springs, cable drums, and centre bearing plate that together create the lifting mechanism for your door. When people refer to torsion bar installation, they typically mean installing or replacing this entire assembly, including the springs that provide the lifting force.

The torsion system works by storing energy as the door closes. When the door moves down, the springs wind tighter around the bar, building tension. When you open the door, either manually or via an automatic opener, this stored energy releases in a controlled manner, effectively counterbalancing the door’s weight and making a heavy door feel almost weightless.

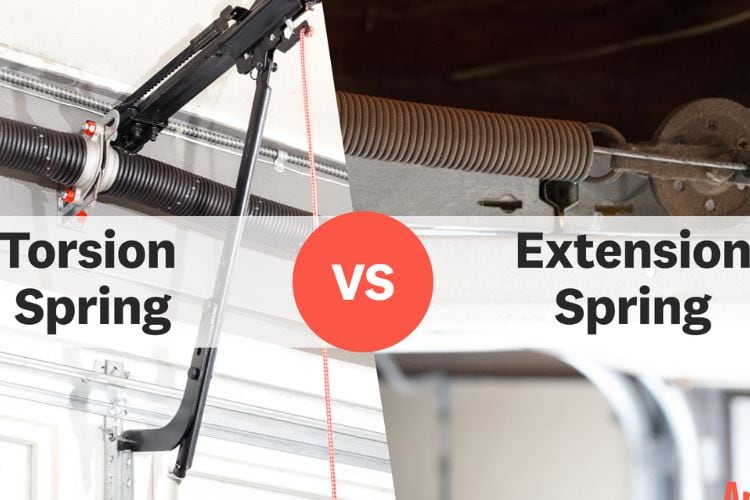

Most modern sectional garage doors in Australian homes use torsion spring systems rather than older extension spring designs. Torsion systems offer smoother operation, longer lifespan, better balance, and improved safety compared to extension springs that stretch along the door tracks.

A faulty or broken torsion bar will dramatically affect your door’s operation—learn what happens when a garage door spring breaks and why attempting to operate your door without a properly functioning torsion system puts your safety and your door’s components at serious risk.

Components of a Torsion Bar System

Understanding the components helps you communicate effectively with technicians and understand what’s involved in installation or replacement. A complete torsion bar assembly includes several interconnected parts that must work together precisely.

The torsion bar itself is a solid or hollow steel shaft, typically 25mm to 40mm in diameter for residential doors. The bar must be straight and strong enough to handle the rotational forces from wound springs without flexing or bending. Cable drums attach to each end of the bar and wind the lift cables as the bar rotates. The centre bearing plate anchors the bar above the door opening and allows it to rotate freely. Torsion springs, either one or two depending on door size, mount on the bar and provide the actual lifting force through their wound tension.

Why Professional Torsion Bar Installation Is Essential

Torsion bar and spring installation is widely regarded as one of the most dangerous DIY repairs a homeowner can attempt. The springs in a torsion system store enormous amounts of energy, enough to lift a door weighing 100 kilograms or more. When that energy releases uncontrollably, the results can be catastrophic.

Statistics from safety organisations indicate that garage door injuries send tens of thousands of people to emergency rooms annually, with spring-related incidents among the most severe. Improperly wound springs can release violently, sending winding bars flying with enough force to cause serious injury or death. Even experienced tradespeople from other fields have been seriously hurt attempting garage door spring work without proper training.

Beyond safety, proper installation requires precise calculations. Springs must match the door’s exact weight and dimensions. The number of wind turns must be calculated correctly for the door height. Cable drum alignment must be perfect. Getting any of these elements wrong results in a door that operates poorly, wears components prematurely, or poses ongoing safety risks.

The torsion bar works in conjunction with your cables and drums to lift the door smoothly—our comprehensive garage door cable repair guide explains how these components interact and why proper cable tension is essential after any torsion bar installation or adjustment.

What Professional Torsion Bar Installation Involves

When you engage a professional for torsion bar installation, the process follows a careful sequence designed for safety and precision. Understanding these steps helps you know what to expect and why the work takes the time it does.

The technician begins by assessing your door, measuring its dimensions, and calculating the correct spring specifications. For replacement jobs, existing spring tension must be safely released using specialised winding bars before any components can be removed. This is the most dangerous phase and requires proper technique and tools.

Installation of the new torsion bar assembly includes mounting the centre bearing plate, positioning the bar, installing springs and cable drums, routing and securing lift cables, and then carefully winding the springs to the calculated tension. Each spring typically requires around 30 quarter-turns for a standard height door, with adjustments based on specific door weight and balance requirements.

The process concludes with balance testing, where the technician disconnects the opener and manually operates the door to verify it holds position at various heights. A properly balanced door should stay in place when released at chest height, indicating the springs are providing correct counterbalance. Final adjustments ensure smooth operation and proper integration with automatic openers.

Torsion Springs vs Extension Springs

If you have an older garage door, it may use extension springs rather than a torsion system. Understanding the differences helps you evaluate whether upgrading makes sense.

| Feature | Torsion Springs | Extension Springs |

| Lifespan | 15,000–20,000 cycles | 5,000–10,000 cycles |

| Operation | Smooth, balanced | Can be jerky |

| Safety | Contained failure | Requires safety cables |

| Maintenance | Less frequent | More frequent |

For most modern installations, torsion systems are the preferred choice due to their reliability, longevity, and smoother operation. If you currently have extension springs, upgrading to a torsion system during your next replacement can provide years of improved performance.

Signs You Need Torsion Bar or Spring Replacement

Torsion springs don’t last forever. Most residential springs are rated for approximately 10,000 cycles, which translates to roughly seven to ten years of typical use. Higher-rated springs can last 15 to 20 years. Several warning signs indicate your torsion system needs attention.

A door that feels unusually heavy when lifting manually suggests springs are losing tension or have broken. Visible gaps in the spring coils indicate a broken spring. Loud banging noises often signal a spring has snapped. If your door opens unevenly, rising faster on one side, one spring may have failed while the other continues working. Any of these symptoms warrant immediate professional inspection.

Environmental factors also affect spring lifespan. In coastal areas like the Gold Coast, salt air can accelerate corrosion on spring steel, potentially reducing service life. Regular lubrication and inspection help identify wear before complete failure occurs.

Cost of Torsion Bar Installation

Professional torsion spring replacement in Australia typically costs between $200 and $350 for standard residential doors, including parts and labour. This covers removal of old springs, installation of new springs matched to your door, and balancing. Complete torsion bar assembly replacement, where the entire shaft and hardware needs replacing, may cost more depending on door size and specifications.

While some websites suggest DIY replacement can save hundreds of dollars, the genuine risks involved make professional installation the only sensible choice. The cost difference is modest compared to potential medical bills, property damage, or the expense of fixing problems caused by incorrect installation. Quality springs installed correctly can provide 10 to 15 years of reliable service, making professional installation excellent value over the system’s lifetime.

A properly installed torsion bar reduces strain on your opener motor and extends its lifespan—discover how torsion systems affect your opener in our garage door motor replacement cost guide and learn why addressing spring issues before motor failure saves you money in the long run.

Maintaining Your Torsion System

Proper maintenance extends spring life and helps identify problems early. Lubricate your torsion springs three to four times per year using a silicone-based lubricant. This reduces friction and prevents rust. Visually inspect springs seasonally for signs of wear, rust, or gaps in the coils.

Test your door’s balance periodically by disconnecting the opener and manually lifting the door to chest height. A properly balanced door should stay in position when released. If it drops or rises, the springs may need adjustment. Never attempt to adjust spring tension yourself as this requires releasing and rewinding the springs under high tension.

If you’re experiencing issues after a torsion bar installation or suspect your torsion system is failing, our garage door troubleshooting guide helps you identify common symptoms like popping sounds, unbalanced operation, and uneven door movement that indicate spring problems.

Frequently Asked Questions

How long does torsion bar installation take?

Professional installation or replacement typically takes one to two hours for standard residential doors. More complex installations or doors requiring custom spring specifications may take longer.

Can I replace just one torsion spring?

While technically possible, replacing both springs simultaneously is strongly recommended. Springs installed at the same time wear at similar rates. If one has failed, the other is likely near the end of its life. Replacing both ensures balanced operation and avoids a second service call.

How do I know what size springs I need?

Spring specifications depend on your door’s weight, height, and track configuration. Professional technicians calculate the correct wire diameter, spring length, and inside diameter based on these measurements. Using incorrect springs results in poor operation and premature wear.

Is it safe to use my garage door with a broken spring?

No. Operating a door with a broken torsion spring is dangerous and can damage your opener, cables, and door panels. The door may drop unexpectedly or the opener may burn out trying to lift the unbalanced weight. Stop using the door and arrange professional repair immediately.

Need Torsion Bar Installation or Spring Replacement?

Whether you need new torsion springs, a complete torsion bar assembly, or repairs to your existing system, professional installation ensures safe, reliable operation for years to come. Attempting this work yourself puts you at serious risk of injury.

A1 Garage Doors Gold Coast provides expert torsion spring installation and replacement across the Gold Coast and Brisbane regions. Our experienced technicians carry the tools and parts needed to complete most spring replacements on the spot, getting your door back to smooth, safe operation quickly.

Call us today on (07) 5515 0277 to arrange an inspection or same-day repair. Visit goldcoastgaragedoorrepair.com.au to learn more about our garage door repair services.